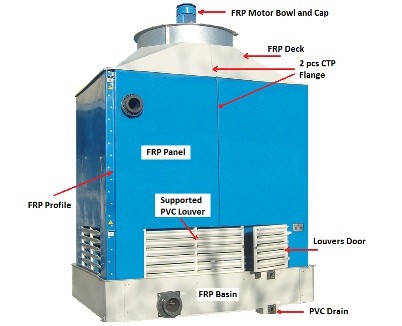

1. Ensotek cooling towers do not need painting for being produced from FRP material.

2. It has resistance to corrosion and chemicals. It does not become rusty and fall down in a few years unlike sheet metal towers.

3. Flame reterdant FRP material using is possible for the hotel, residence, hospitals etc.

Ensotek Cooling Tower Features

4. As Fills;

4.1. PP ring fill , made of PP ( Polypropylene), is used in such facilities where water is dirty, greasy, oxide layered, prone to calcification and environment is very dusty. PP material can even be used successfully at 100 °C process waters. Occlusion risk is low and it is easy and possible to clean for reuse.

4.2. PVC Film fills are used in such facilities where water is clean (purified from oil, lime, residue ,and dirt) and dust and dirt free environments. As it has more wet surface, its cooling performance is better than other fill types.

4.3. Splash grid fills are used for very dirty process waters. Such as tomate paste process, sugar factories, oil factories vacuum processes.

5. Materials are in harmony. In FRP structure , there is no metal or wooden material. Burden resistance panels are ensured by import Coremat material in 33 mm thickness. For this reason, it can serve 30-40 years.

6. Maintenance cost is small compared to metal sheet towers.

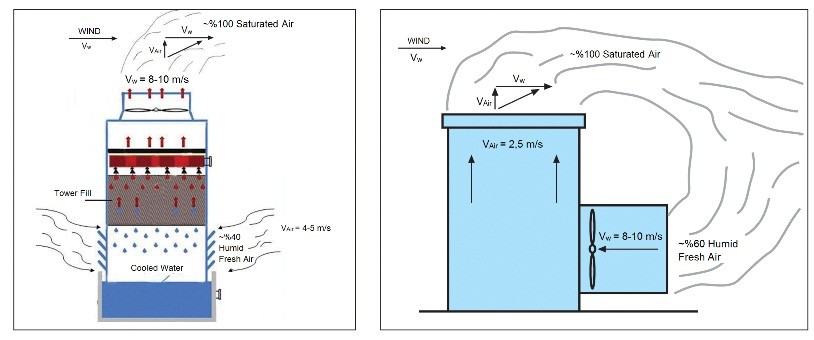

7. In towers which absorbs air from above, energy, consumed by fan is lower compared to ones that are push from below. It moves away from tower angle as the ascent rate of wet air is high. There is no possibility to be absorbed again by fan.

In below pushing towers, as ascent rate of air , thrown from tower , is very slow and density is too much , it cannot be moved away from tower angle , which causes wet air being absorbed by tower. For that reason, towers, absorbing air above , provide 1,5-2 times energy saving compared to below pushing towers.

8. As its cooling performance and wet bulb temperature are good, it raises the efficiency of facilities and does not cause product loss, provides system’s energy saving.

9. Although first investment cost is high compared to metal sheet towers, it provides savings from maintenance and operating costs; so it is the most reasonable tower for users.

10. Replacement supply is very easy and cheap.